Steel Structure

- This kind of steel works, with environmental protected materials, is easy and fast in installation, and saves costs in time, labors and materials; what's more, practical, stable and safe in constructions.

- This kind of steel works contains the characteristics of a high degree of industrialization, small spatial loading-bearings, light weight, strong stability, good seismic performance and artistically appearance

- Applications: This kind of steel works can be widely used in steel workshops, warehouses, restaurants, gymnasiums, hypermarkets, leisure buildings, stadiums, platforms, exhibition centers, dome canopies, hangars, curtain walls, space frames.

Steel Fabrication

- Steel Metal fabrication is a value added process that involves the construction of machines and structures from various raw materials. A fab shop will bid on a job, usually based on the engineering drawings, and if awarded the contract will build the product. Fabrication shops are employed by contractors, OEM's and VAR's. Typical projects include; loose parts, structural frames for buildings and heavy equipment, and hand railings and stairs for buildings.

- Fabrication as an industrial term refers to building metal structures by cutting, bending, and assembling. The cutting part of fabrication is via sawing, shearing, or chiseling (all with manual and powered variants) and via CNC cutters (using a laser, plasma torch, or water jet).

- The bending is via hammering (manual or powered) or via press brakes and similar tools. The assembling (joining of the pieces) is via welding, binding with adhesives, riveting, threaded fasteners, or even yet more bending in the form of a crimped seam. Structural steel and sheet metal are the usual starting materials for fabrication, along with the welding wire, flux, and fasteners that will join the cut pieces.

- As with other manufacturing processes, both human labor and automation are commonly used. The product resulting from (the process of) fabrication may be called a fabrication. Shops that specialize in this type of metal work are called fab shops.

- The end products of other common types of metalworking, such as machining, metal stamping, forging, and casting, may be similar in shape and function, but those processes are not classified as fabrication...

Tanks

- Steel Storage Tank Design and Application - Storage tanks made from stainless steel are used throughout industry in many configurations which depend upon functional requirements. These functional requirements include: capacity, storage median, operating environment, and installation requirements.

- The orientation of the installed tank should be determined and a static or portable installation where the tank can be moved from one place to another, via wheels, casters or other devices. The storage tank installation should minimize all piping, especially exterior pipes in which hazardous materials flow or a solution can freeze if a failure occurs in the heating or environmental control equipment. Additionally, the storage tank and piping should located within a low-traffic area to minimize exposure to other equipment or personnel.

- Vertical storage tanks are preferred rather than horizontal tanks since they take up less floor space. Tank should be supported on a adequate foundation, such asphalt or concrete. Connections at the top of a tank should be designed such that they are within one area near the edge of the tank to permit access for maintenance. The storage tank inlet is typically designed at the highest anticipated tank level with a pipe that extends and accesses the lowest tank level. The inlet pipe should have a siphon feature on the opposed side of the tank from the discharge location.

- An atmospheric vent feature is normally included that is open all times. Fault sensors and safety features should also be considered as follows: high-level, high pressure, low level, temperature, pressure relief, sight glasses, etc.

- Storage tank may require insulation depending on storage medium and performance at low temperature. Stainless steel is required in applications where the storage medium or environment is caustic or minimal contamination is required.

Silos

- A silo is a structure for storing bulk materials. Silos are used in agriculture to store grain (see grain elevators) or fermented feed known as silage. Silos are more commonly used for bulk storage of grain, coal, cement, carbon black, woodchips, food products and sawdust. Three types of silos are in widespread use today - tower silos, bunker silos and bag silos. Missile silos are used for the storage and launching of ballistic missiles;

- There are different types of cement silos such as the low-level mobile silo and the static upright cement silo, which are used to hold and discharge cement and other powder materials such as PFA ( Pulverized Fuel Ash). The low-level silos are fully mobile with capacities from 10 to 75 tons. They are simple to transport and are easy to set up on site. These mobile silos generally come equipped with an electronic weighing system with digital display and printer. This allows any quantity of cement or powder discharged from the silo to be controlled and also provides an accurate indication of what remains inside the silo. The static upright silos have capacities from 20 to 80 tons. These are considered a low-maintenance option for the storage of cement or other powders. Cement silos can be used in conjunction with bin-fed batching plants.

- Tower silo- Concrete stave silos- Low-oxygen tower silos- Bunker silos- Bins.

Insulation and cladding Works

External wall insulation system (or EWIS) is a thermally insulated, protective, decorative exterior cladding system which consists of foamed polystyrene, mineral wool polyurethane foam ,mineral or synthetic plaster.

- Aluminum Composite Panel (ACP) or Aluminum Composite Material (ACM) is a widely-used term describing flat panels that consist of a non-aluminum core bonded between two aluminum sheets. Aluminum sheets can be coated with PVDF or Polyester paint. ACPs are frequently used for external cladding of buildings (building facades), for insulation and for signage.

- Rain screen cladding is a construction facade rain screen system which consists of the sub frame(Stofix) and different finishes like Sunstone cladding panels, brick, ceramic tiles, reconstituted stone boards (Stone Sheets), ceramic granite based on a natural stone, high-pressure laminates, composite aluminum panels, metal panels (aluminum, zinc, steel) (Knight Series Metal Panel System) or fiber-cement board, or durable exterior woods.

- Carbon Cast is a precuts concrete technology that uses carbon fiber grid as secondary reinforcing or as a shear truss. It was introduced by Altus Group, Inc., a national partnership of 13 precut concrete manufacturers and seven industry suppliers founded to expedite the research and national commercialization of concrete innovations.

• Products to meet latest building regulations

• Suitability of products application and systems

• Matching and finding Old/Deleted Profiles

• Gutter Calculations - important when over roofing

• Widest range of products from UK and Europe

• Take off service

• On-site measuring and design

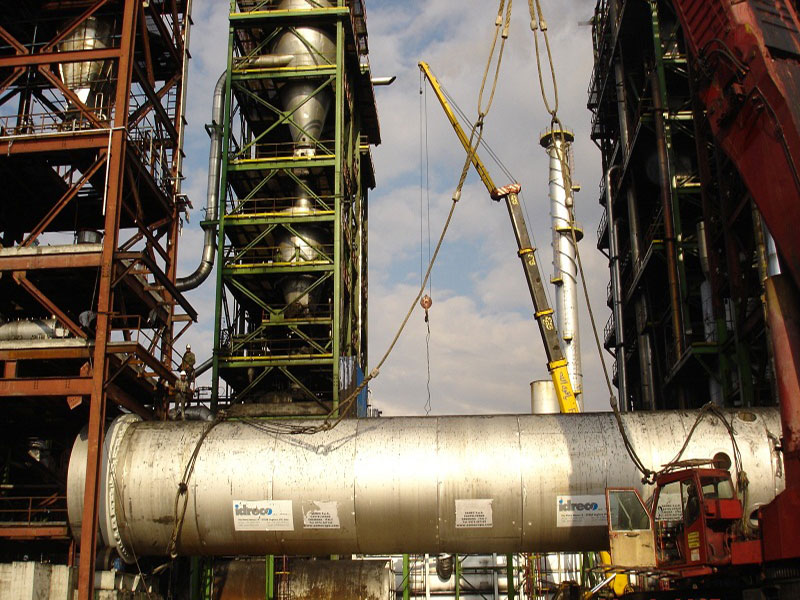

Equipments Installation

- Steel Works, Inc. has the personnel, ability and equipment to fabricate a wide variety of made to order items. Our willingness to work with you in design build projects goes a long way in supplying a finished project that is tailored to your needs.

- Steel Works, Inc. realizes the need and importance additional energy sources. We are focusing new efforts in supplying steel components used in wind turbine tower concrete bases. To date, our capacity has been limited to parts.

Piping

- Within industry, piping is a system of pipes used to convey fluids (liquids and gases) from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.[1][2]

- Industrial process piping (and accompanying in-line components) can be manufactured from wood, fiberglass, glass, steel, aluminum, plastic, copper, and concrete. The in-line components, known as fittings, valves, and other devices, typically sense and control the pressure, flow rate and temperature of the transmitted fluid, and usually are included in the field of Piping Design (or Piping Engineering). Piping systems are documented in piping and instrumentation diagrams (P&IDs). If necessary, pipes can be cleaned by the tube cleaning process.

- "Piping" sometimes refers to Piping Design or the performance of the actual layout of the physical piping within a process plant or commercial building. In earlier days, this was sometimes called Drafting, Technical drawing, Engineering Drawing, and Design but is commonly performed by Designers who have learned to used automated computer aided drawing/computer aided design (CAD) software.

- Plumbing is a piping system that most people are familiar with, as it constitutes the form of fluid transportation that is used to provide potable water and fuels to their homes and business. Plumbing pipes also remove waste in the form of sewage, and allow venting of sewage gases to the outdoors. Fire sprinkler systems also use piping, and may transport potable or nonpotable water, or other fire-suppression fluids.

- Piping also has many other industrial applications, which are crucial for moving raw and semi-processed fluids for refining into more useful products. Some of the more exotic materials of construction are Inconel, Titanium, chrome-moly and various other steel alloys.